The field of material science relies heavily on the continuous testing and analysis of materials to ensure their durability and performance in various applications. One key aspect of this process is fatigue testing, which involves subjecting materials to repeated stress and strain to simulate real-world conditions.

Fatigue testing machines play a critical role in this process, allowing researchers to evaluate the endurance and lifespan of materials under different conditions. By subjecting materials to repeated loading and unloading cycles, researchers can uncover potential weaknesses and vulnerabilities that may lead to failure over time.

This comprehensive testing approach helps to ensure the quality and reliability of materials used in a wide range of industries, from aerospace and automotive to construction and electronics. In this article, we will explore the importance of fatigue testing machine in material science and how they contribute to the advancement of technology and innovation.

History and Evolution of Fatigue Testing Machines

The history and evolution of fatigue testing machines is a fascinating journey that dates back centuries, beginning with the simple manual apparatus used by early metallurgists to test the endurance of metal structures. Over time, advancements in technology led to the development of more sophisticated machines capable of applying varying levels of stress and strain to materials, allowing scientists to study the behavior of different materials under repeated loading conditions.

From the development of hydraulic and pneumatic machines in the early 20th century to the modern computer-controlled systems used today, fatigue testing machines have played a critical role in advancing our understanding of material science and ensuring the durability and reliability of products across various industries.

Key Components and Functionality of Fatigue Testing Machines

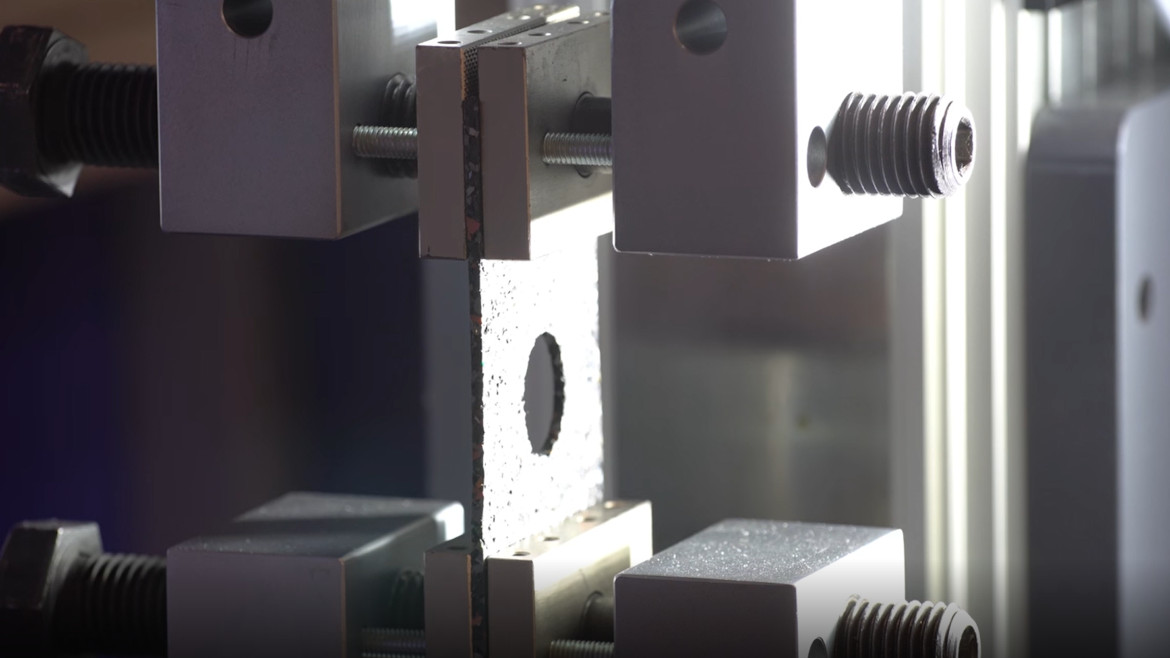

Fatigue testing machines play a critical role in material science by subjecting samples to repeated stress to simulate real-world conditions and evaluate their endurance limits. The key components of these machines include a high-strength frame to hold the specimen, a servo-hydraulic actuator to apply the cyclic load, and a data acquisition system to record and analyze the resulting data. The functionality of fatigue testing machines lies in their ability to accurately control the loading conditions, measure the number of cycles until failure, and provide valuable insights into the fatigue behavior of materials.

This information is essential for engineers and researchers to design and improve the durability of various products and structures, ultimately ensuring their safety and reliability in service.

Applications and Benefits of Fatigue Testing in Material Science

The applications and benefits of fatigue testing in material science are vast and essential for ensuring the safety and reliability of various products and structures. By subjecting materials to repeated loading and unloading cycles, fatigue testing helps researchers and engineers understand how materials degrade over time, leading to the development of more durable and long-lasting products.

Additionally, fatigue testing provides valuable insights into the mechanical behavior of materials under real-world conditions, allowing for the optimization of design parameters and the prediction of potential failure points. Overall, the use of fatigue testing machines in material science plays a critical role in advancing technology and improving the quality and performance of numerous industries.

Future Trends and Innovations in Fatigue Testing Technology

As the field of material science continues to evolve, so too do the technologies used for fatigue testing. Future trends in fatigue testing technology are pointing towards more advanced and efficient machines that can accurately simulate real-world conditions.

Innovations such as AI-driven algorithms, remote monitoring capabilities, and integrated data analysis software are revolutionizing the way fatigue tests are conducted. These cutting-edge developments not only enhance the accuracy and reliability of fatigue testing results but also streamline the testing process, saving time and resources for researchers and engineers.

By staying at the forefront of these technological advancements, materials scientists can push the boundaries of what is possible in terms of understanding and predicting material fatigue behavior.

Conclusion

In conclusion, fatigue testing machines play a crucial role in material science by accurately assessing the endurance and durability of various materials under repetitive stress. These machines provide vital data that help researchers and engineers understand the mechanisms of material fatigue, leading to the development of stronger and more reliable products.

By simulating real-world conditions and pushing materials to their limits, fatigue testing machines contribute significantly to advancements in material science and innovation. These machines are indispensable tools in the quest for enhancing the performance and longevity of materials in various industries.